MEMS technology

– Micromechanical precision for demanding applications

The miniaturisation made possible by MEMS (micro-electromechanical systems) revolutionises inertial sensor technology.

Technology that sets global standards

LITEF develops state-of-the-art inertial navigation and stability solutions as well as sensor systems with a focus on the latest technologies. Through continuous advances in MEMS technology, LITEF develops solutions that is a cut above the rest in terms of robustness.

Pushing the boundaries of what is possible

At the beginning of the 2000s, LITEF began developing micromechanical gyros (MEMS). Today, MEMS and FOG technology are still the core technologies at LITEF, and provide the basis for the development and production of innovative and ITAR-free products for various applications and mission types.

Through the further development of FOG and MEMS technologies, LITEF is able to offer inertial reference systems which are characterised by low weight, low volume and low power loss with high sensor data accuracy.

Innovation that sets standards

LITEF intends to maintain its leading market position in the areas of FOG, MEMS and sensor fusion solutions also in the years to come. The company will continue to explore and redefine what is feasible using its systems expertise.

MEMS excellence for tomorrow’s navigation

Technological competence and development focus

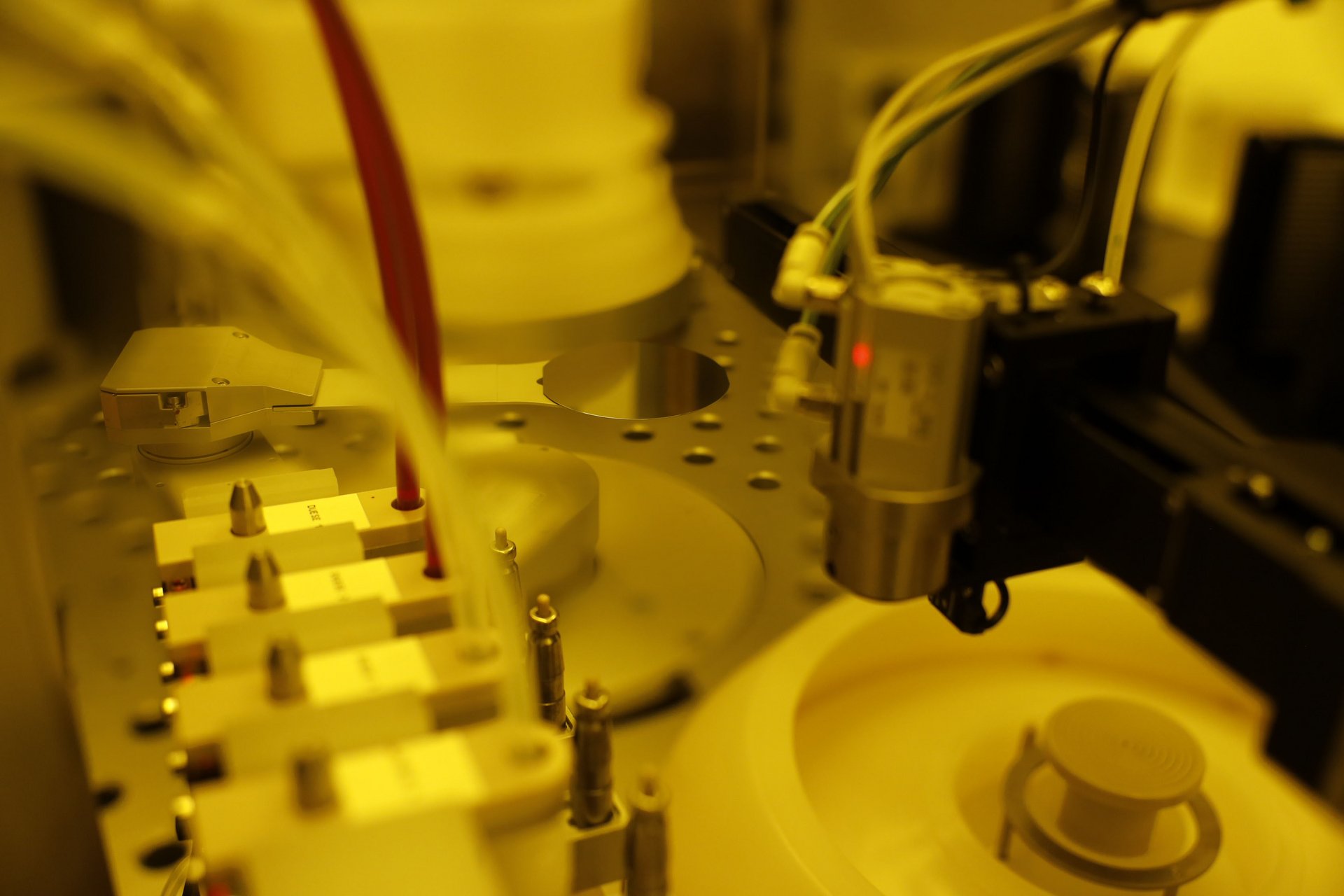

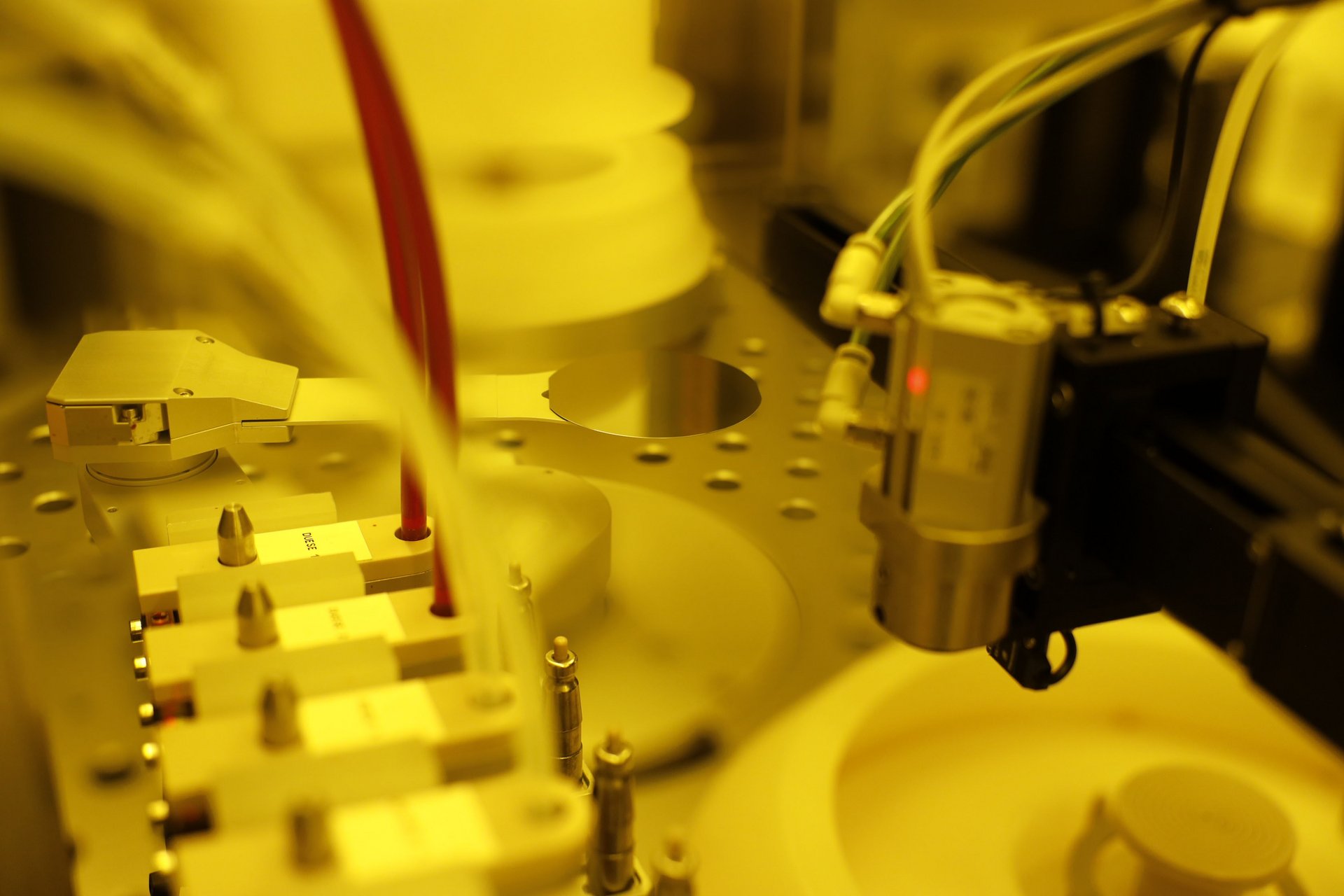

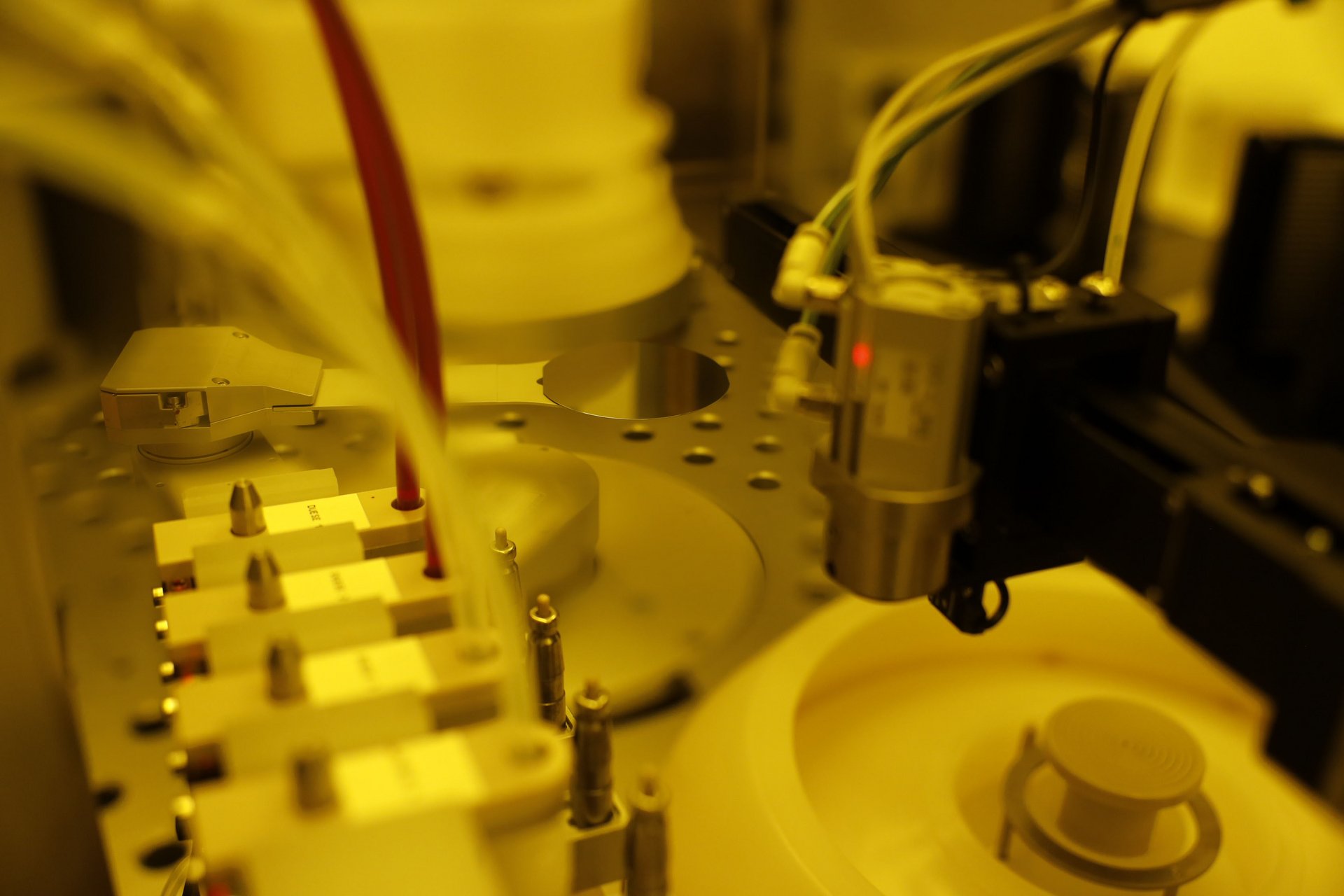

Our MEMS products are based on in-depth expertise in MEMS sensor design and FEM simulation, high-precision MEMS production in our own clean room, assembly & packaging of MEMS sensors, calibration and error compensation, signal evaluation by sensor ASICs developed in-house as well as mechanical and thermal robustness.

Outlook: MEMS for gyrocompassing

While classic MEMS IMUs are not yet able to achieve the precision of optical systems such as FOG (fibre optic gyroscopes) sensors, LITEF is working to close this technological gap. Our goals: The development of MEMS-based sensor solutions that enable precise gyrocompassing. This means reliable north finding based purely on MEMS inertial sensors, use without external reference systems such as GNSS or magnetic field sensors as well as compact, robust and cost-efficient navigation solutions. This enables MEMS technology to penetrate into a field that was previously reserved exclusively for high-priced optical systems and opens up new application possibilities, especially in the safety-critical and mobile sectors.

Why MEMS from LITEF?

Our MEMS sensor solutions are specifically designed for the most demanding applications and reliably deliver the promised performance under the toughest environmental conditions.

Whether under shock loads, at extreme temperatures or in highly dynamic systems: MEMS products from LITEF stand for precision, stability and technological excellence – Made in Germany.