Six decades ahead – always one step further

LITEF is a pioneer of the latest inertial sensor technology – from robust MEMS and FOG systems to intelligent sensor fusion.

LITEF – where standards are born

With more than six decades of experience in the development of inertial systems, we continuously define new standards. From mechanical gyros to fibre optic technology to micromechanical sensors – LITEF combines proven German engineering with innovative future technologies.

Our solutions enable reliable navigation and precise positioning for the most demanding applications worldwide. As one of the leading companies in the field of inertial technology, LITEF continuously tests the boundaries of what is technologically feasible.

Rethinking navigation – actively shaping the future

Redefining the technologically feasible

Out strategy for the future is defined by three core technologies: FOG precision, MEMS innovation and intelligent sensor fusion. With the world-famous German attention to detail in engineering, we are continuously opening up new limits to what is technically feasible.

60+ years of inertial technology leadership

250,000 FOG axes in use worldwide

100 % ITAR-free availability

Future position – navigation and timing

The future of navigation lies in the intelligent combination of proven technologies with groundbreaking innovations. LITEF is actively helping to shape this future with:

Modern navigation algorithms

Development of advanced algorithms for precise navigation in the most complex environments

Incorporation of innovative sensors

Continuous integration of new sensor technologies to improve navigation accuracy

Driving technological advances in enabling technologies

Focus on miniaturisation, microelectronics, artificial intelligence and quantum sensors

Benefits of open standards and architectures

Future-proof system integration through standardised interfaces

Technology forecasting

Systematic assessment and prediction of future technological developments

What is thought impossible today is the LITEF standard tomorrow. We aspire to continuously redefine the technological possibilities and to thereby provide you with decisive competitive advantages.

LITEF intends to maintain its leading market position in the areas of FOG, MEMS and sensor fusion solutions also in the years to come. With our system knowledge, we continuously push the boundaries of what is technologically feasible.

Overcoming limits through innovation

Precision without compromise – as individual as your requirements

Standard solutions are the beginning, not the end, of our possibilities. Basing our work on direct dialogue with customers, we develop systems that exactly meet your specific requirements. German engineering stands for precision and reliability without compromise.

Through the continuous further development of key technologies in Germany, we ensure you a leading technological position and long-term innovative strength.

Systems that decide, control and protect lives

LITEF technology is more than sensors – it is the basis for systems that decide, control and protect lives. Place your trust in proven German state-of-the-art technology for the most demanding navigation and positioning tasks.

Quality as a promise

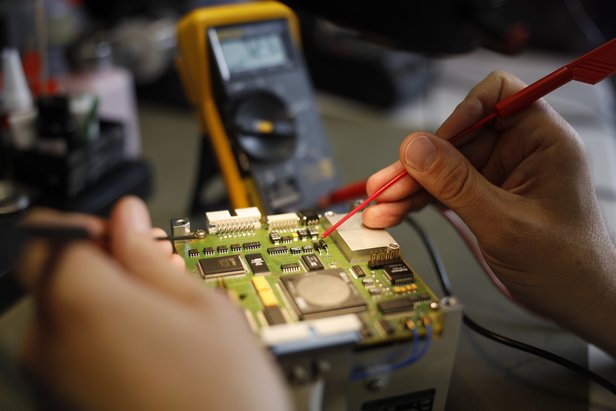

From our location in Freiburg, we develop navigation solutions that set new standards around the world. Several key technologies underpin our products we develop and manufacture: closed loop inertial sensors, dynamically tuned gyros, fibre optic gyros, MEMS gyros and accelerometers, as well as electronic components and ASICs.

Our manufacturing processes follow the strictest standards, ensuring quality you can rely on.

Reliability is not a coincidence – but a system understanding

Over six decades of experience in critical applications have taught us that reliability is not created by chance, but by system understanding and consistent quality. As your partner for inertial technology, we not only guarantee product quality, but also systemic safety for your most challenging missions.

Products from LITEF are in use worldwide, with applications ranging from civil and military aviation, land and marine applications, through to industrial applications. Proven in all critical application scenarios with ITAR-free German state-of-the-art technology.